JAOUR and TALY Shine as “Dual Giants” at Labelexpo Asia 2025 with Innovative Hot Melt Adhesive and Silicone Release Agent Solutions

2025-12-06

Shanghai, China, December 2-5, 2025 – Jaour Hot Melt Adhesive, a leading player in China's hot melt adhesive sector, made a significant impact as a "Dual Giants" presence with its subsidiaries JAOUR Hot Melt Adhesive and TALY Technology at the 2025 Asian International Label Exhibition (Labelexpo Asia 2025), the largest label and package printing industry event in the Asia-Pacific region held at the Shanghai New International Expo Centre.

The companies drew substantial attention with their innovative products and professional solutions.JAOUR showcased its professional hot melt adhesive solutions, honed over 19 years of industry dedication. Adhering to the philosophy of "better bonding, better life," JAOUR's JaourTak® series of hot melt adhesive products have earned consistent praise and customer trust through extensive validation in domestic and international markets.The exhibit featured a comprehensive range of hot melt adhesive solutions for various labels and specialized applications. These included solutions for PP synthetic paper labels, coated paper labels, thermal paper labels, film labels, RFID electronic labels, tire labels, removable labels, and freeze-resistant labels, among other scenarios. These products attracted numerous professional visitors for in-depth exchanges, thanks to their environmental features and outstanding performance.

The JaourTak® series products are solvent-free, contain very low VOC levels, and have secured multiple international certifications including FDA, GOTS, OEKO-TEX, REACH SVHC, RoHS, and PAHs. These certifications ensure the products meet international environmental and safety standards, providing reliable and safe bonding solutions for the label industry.

Although Labelexpo Asia 2025 has concluded successfully, the dedication of JAOUR Hot Melt Adhesive to serving its clients remains as strong as ever. The company will continue to focus on the innovation and application of hot melt pressure-sensitive adhesives. Upholding its values of "Customer First, Honesty and Trustworthiness, Sincere Collaboration, and Embracing Innovation," JAOUR is committed to providing more efficient, stable, and environmentally friendly solutions to support the robust development of the global label printing industry.

We look forward to meeting again at the next exhibition.

View More

How to applicate your hot melt adhesive in cold weather properly

2025-10-30

As temperatures gradually drop in some regions, many customers using hot melt pressure-sensitive adhesive (HMPSA) have begun reporting issues with inadequate bonding performance. As a professional HMPSA solutions supplier, Jaour fully understands the challenges that winter low temperatures pose to production processes. This article will explain in detail the reasons for the decline in HMPSA performance during winter and provide a series of practical solutions to help you maintain the stability and consistency of your production quality throughout the colder months.

Temperature is a critical factor affecting the performance of HMPSA. The low-temperature conditions in winter can impact HMPSA performance in several ways:

Low temperatures cause the molecules of HMPSA to move more slowly, preventing them from rapidly wetting the surface to be bonded.

Fig 1. Influence of temperature on particle motion and thermal expansion

At the same time, as the temperature drops, the modulus of the adhesive increases sharply. When the same pressure is applied, the adhesive undergoes less deformation, resulting in a smaller effective contact area compared to that under normal temperatures. This ultimately leads to subpar bonding strength.

Fig 2. A typical rheological spectrum of hot melt adhesive

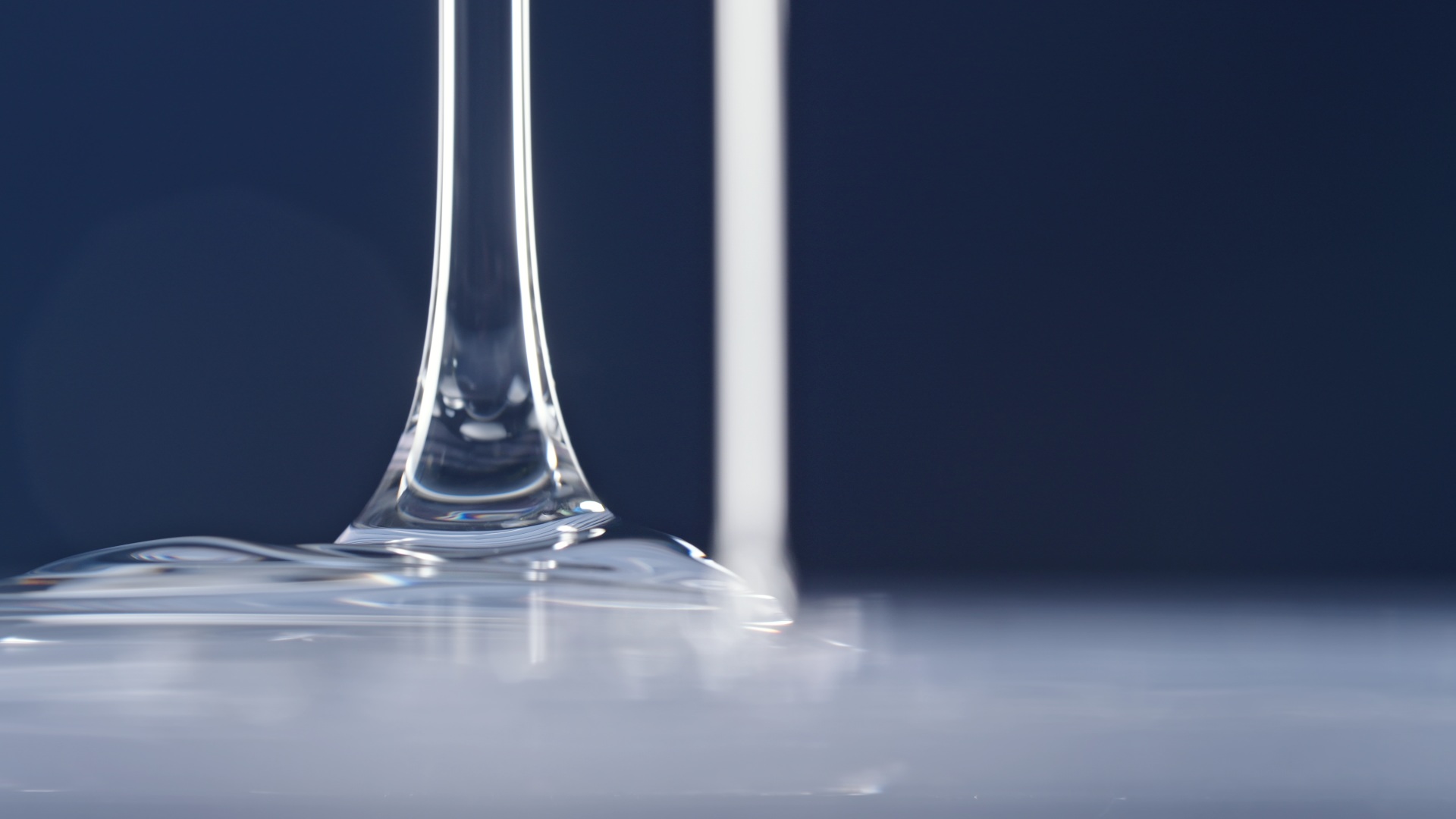

When hot melt adhesive is extruded from the applicator nozzle, it is in a molten state. In a warm environment, it can remain fluid for several seconds (in its open time), allowing it to penetrate into the fine pores and irregularities of the substrate. However, in winter, as soon as the molten adhesive comes into contact with the cold substrate surface, it rapidly cools and solidifies. This causes a sharp increase in viscosity and a drastic reduction in flowability, leaving insufficient time for effective penetration.

Fig 3. a) Good flowability of adhesive b). Low flowability of adhesive at low temperature

Here are suggested solutions for addressing potential problems of using hot-melt adhesive in cold weather.

Solution 1: Use the most appropriate adhesive.

For specific applications such as label adhesives, Jaour has developed special winter and summer HMPSA formulations to address challenges posed by temperature variations. Additionally, high-temperature and freeze-resistant label adhesives are available for more extreme temperature conditions. The winter-grade adhesive maintains molecular mobility even at lower temperatures, ensuring reliable performance in cold environments. This winter-formulation HMPSA features a lower application temperature range, retaining excellent flowability and wetting behavior under low-temperature conditions.

If you are currently using a summer-grade product, it is recommended to switch to the winter formulation in a timely manner. Generally, September to October (in East Asia) is the optimal window for transitioning to winter-grade products. Alternatively, based on actual conditions, ensure to stock up on the winter version before temperatures drop to facilitate a seamless transition.

Solution 2: Adjust the temperature of adhesive application system, coating weight, and substrate.

To address bonding challenges in winter, the following adjustments to the hot melt adhesive application process are recommended:

Increase the operating temperature: It is generally advised to raise the working temperature of the hot melt adhesive by 5-10°C compared to summer settings. This enhances its fluidity and reduces instances of poor adhesion. However, care must be taken not to exceed the maximum withstand temperature of the adhesive, as this could lead to rapid thermal degradation of the adhesive or damage to the substrate.

Adjust the adhesive coating weight: To compensate for the reduction in bonding strength caused by lower temperatures, appropriately increasing the amount of adhesive applied can help achieve the required bonding performance.

Pre-heat the substrates: Pre-heating the substrates to be bonded is an effective method to improve winter bonding results. When warm adhesive comes into contact with a cold substrate surface, the material rapidly draws heat from the adhesive, causing the adhesive at the interface to lose fluidity almost instantly. Pre-heating the materials prevents this issue. It is recommended to raise the substrate temperature above 15°C.

Ensure adequate equipment pre-heating: Fully pre-heating the application equipment, such as the glue gun, before use is crucial. This maintains the hot melt adhesive at a sufficiently high temperature, thereby extending its fluidity window.

Solution 3: Modify the condition of workshops and warehouses

It is essential to ensure the ambient temperature of the workshop is maintained above 15°C. When necessary, regional heating methods, such as using a heat gun, can be conducted. Clients may also consider upgrading their production lines to constant-temperature workshops, which fundamentally address bonding challenges in low-temperature operations.

Furthermore, bonded components require a conditioning period under suitable temperature conditions to achieve their ultimate strength. During this process, it is crucial to avoid exposing the bonded parts prematurely to low-temperature environments or subjecting them to load.

Solution 4: Remind your clients of pre-treating materials in cold weather

Low-temperature storage can "freeze" the molecular movement of HMPSA, preventing it from effectively wetting the substrate. It can also transition the adhesive from a semi-solid state to a brittle, non-tacky glassy state, resulting in a reduction or even complete loss of initial tack.

If samples have been stored in a low-temperature environment, it is advisable for your customers to let the adhesive acclimate at room temperature for a period before use. This allows the adhesive to warm up, which helps restore its bonding performance.

Furthermore, conventional winter-grade label adhesives typically have a minimum application temperature of 0°C. For applications requiring bonding at 0°C or below, specialized low-temperature adhesives or even freeze-resistant grades should be used.

View More

Jaour Hot Melt Adhesive Obtains IATF 16949:2016 Certification, Marking a Major Step into the Global Automotive Supply Chain

2025-09-23

Jaour Hot Melt Adhesive has successfully achieved the IATF 16949:2016 certification, the internationally recognized Automotive Quality Management System standard often regarded as the industry's "quality passport." This accomplishment signifies that Jaour's quality management system fully complies with the highest international standards for the automotive industry, laying a solid foundation for its entry into the global automotive supply chain market .

Developed by the International Automotive Task Force (IATF), IATF 16949 is a global standard that integrates automotive-specific requirements with the ISO 9001 framework . Renowned for its comprehensiveness and rigor, obtaining this certification demonstrates that Jaour meets the stringent quality requirements of the global automotive industry in product design, development, production, and service .

A Global "Access Pass" for the Automotive Supply Chain

The IATF 16949 certification process is extremely rigorous, extending beyond documentation review to encompass a comprehensive management philosophy . It emphasizes process orientation and risk-based thinking, requiring organizations to not only consistently produce conforming products but also establish mechanisms for defect prevention, waste reduction, and continuous improvement . As global automotive OEMs and Tier-1 suppliers increasingly mandate this certification for partners, it serves as a "golden key" for Jaour to expand its market access and enhance its competitiveness and brand reputation worldwide .

Comprehensive Quality Enhancement

In preparation for the certification, Jaour undertook a thorough "quality revolution" involving employees at all levels. The company systematically reviewed and optimized all core processes—from order review and product design to manufacturing and supplier management—ensuring traceability, verifiability, and risk control . Investments were made in advanced production and testing equipment to ensure manufacturing precision and stability. Furthermore, Jaour established robust data collection and analysis systems, utilizing tools like SPC for real-time process monitoring, thereby creating a self-driven cycle for quality improvement .

A New Chapter Begins

Securing the IATF 16949 certification is a significant milestone for Jaour Hot Melt Adhesive . The company remains committed to its core values of quality, innovation, and collaboration, striving to deliver superior, safe, and reliable products and solutions to its customers worldwide.

View More

Jaour sincerely invites you participate in the 20th China Shanghai International Automotive Interiors and Exteriors Exhibition

2025-08-05

Jaour's products that are applied in the automotive industry

To know more about the products of GUIBAO applied in the automotive industry, please click the link below

http://www.guibao.cn/download/ueditor/file/6372014824728262501123313.pdf

View More